Back to top

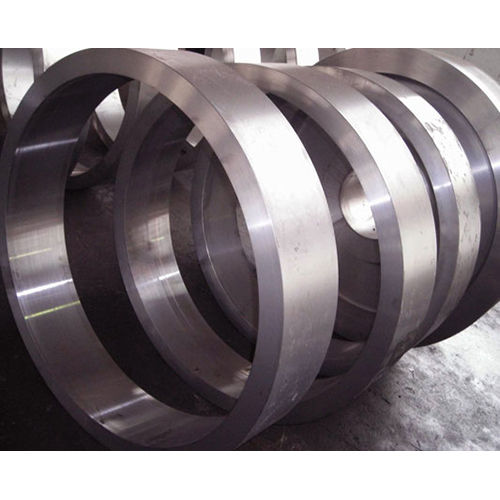

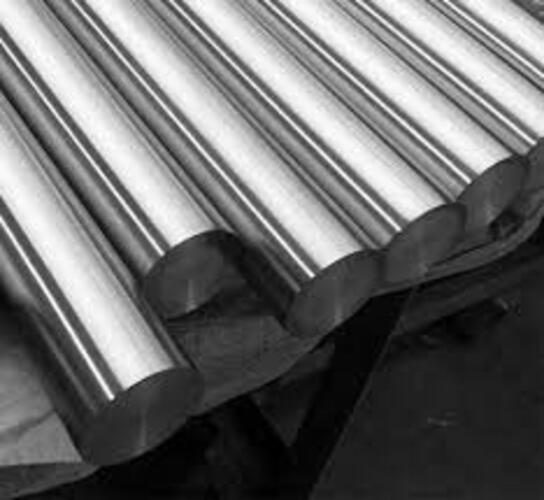

Reliable and Durable Industrial Flanges, Industrial Rings, SS Circle, etc. Available

In Precise Dimensions For Every Need

JP Metal India is a notable manufacturer and trader of industrial

flanges, industrial rings, SS circles, etc. Ever since our formation, we

have been strengthening a large number of manufacturers by providing

high-quality products. The entire range is manufactured using the latest

technology that ensures optimum durability and reliability.

Further, we also ensure that before the final delivery, the products are tested for various quality parameters. It allows us to increase our credibility in the market, which results in a large number of clients all over the world.

Research and Development Facility

Over the years, we have been able to become a large company due to our special focus on research & development facilities. Our R&D tasks aid in regular up-gradations of the product line, reduction of production cost, and knowledge about the exact views of customers about products and the firm's policies.

Infrastructure We Own

A modern infrastructure is owned by us to have smooth and swift execution of all the business operations. The company has built two specialized manufacturing cells where several types of machines and tools are updated that aid in making the gamut at an outstanding speed. To retain high production speed, our facilities are regularly oiled and upgraded.

Why Choose Us?

We assure clients that we offer the best customized elevators, which are made after considering the specifications of customers. Moreover, some of the other exceptional aspects of our business are:

Further, we also ensure that before the final delivery, the products are tested for various quality parameters. It allows us to increase our credibility in the market, which results in a large number of clients all over the world.

Research and Development Facility

Over the years, we have been able to become a large company due to our special focus on research & development facilities. Our R&D tasks aid in regular up-gradations of the product line, reduction of production cost, and knowledge about the exact views of customers about products and the firm's policies.

Infrastructure We Own

A modern infrastructure is owned by us to have smooth and swift execution of all the business operations. The company has built two specialized manufacturing cells where several types of machines and tools are updated that aid in making the gamut at an outstanding speed. To retain high production speed, our facilities are regularly oiled and upgraded.

Why Choose Us?

We assure clients that we offer the best customized elevators, which are made after considering the specifications of customers. Moreover, some of the other exceptional aspects of our business are:

- Wide supply chain

- Reasonable rates

- Timely delivery

- Quality assurance

Send Inquiry

Send Inquiry Send SMS

Send SMS